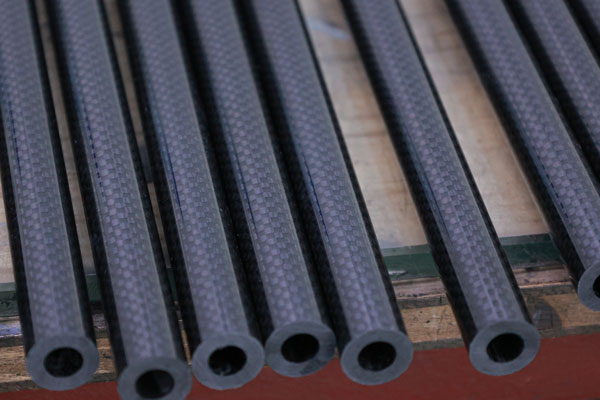

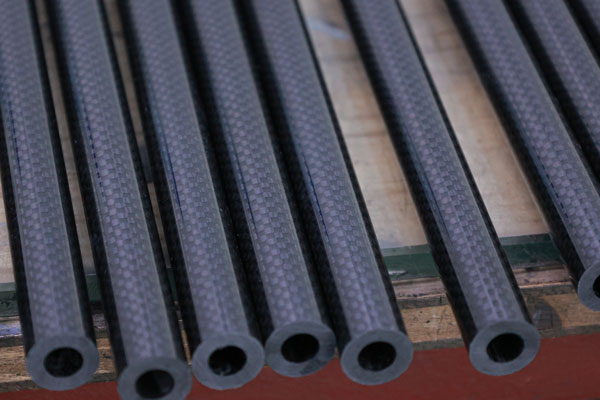

How to improve the material of carbon fiber pipes?

Carbon fiber is widely used due to its superior strength and excellent weight reduction effect compared to steel. Carbon fiber pipes are the main application form, and usually there are defects in certain parts of carbon fiber pipes. Therefore, it is particularly important to improve the quality of pipes. Based on the experience summarized in the production process of Kaida Carbon Fiber for many years, this article mainly introduces how to improve the quality of carbon fiber pipes.

Since we want to improve the quality of carbon fiber pipes, it is necessary to first understand the causes of defects in carbon fiber pipes. Generally, the surface defects of carbon fiber pipes mainly include wrinkles, stripes, and other problems. Tracing the causes mainly focuses on the pre impregnated layer laying process. If sufficient tension is not applied during the laying process to compress the pre impregnated layer quickly, it will make each layer of pre impregnated material relatively loose, and the overall thickness will also increase. But if pressure is applied, it will bring contraction force, causing the carbon fibers to bend and fold. And, some auxiliary materials are also needed during the pre impregnated layer laying, which can cause wrinkles during compression.

After explaining the reasons, we will now introduce the solution to everyone. The first important step is to combine pre pressing with temperature during the laying process of carbon fiber prepreg. Generally, after each few layers are laid, pre pressing is carried out at a certain temperature. Timely pre pressing can prevent the accumulation of fiber relaxation layers. The resin content and pipe thickness in carbon fiber composite materials can be effectively controlled. Secondly, selecting the appropriate mold is also very important. The selection of the mold has a significant impact on the outer diameter size. For the production material of the core mold, a metal material with good rigidity is also needed to improve the density and rigidity of carbon fiber pipes. In addition, the heat shrink process can also be used to improve the surface quality and accuracy of carbon fiber pipes.